The Premier Guide to Car Spare Parts Manufacturers

In the ever-evolving landscape of the automotive industry, car spare parts manufacturers play a crucial role in ensuring that vehicles remain on the road and perform optimally. With the increasing complexity of automotive designs and technologies, the demand for high-quality spare parts has surged, making it essential for both manufacturers and consumers to be aware of what defines a reputable manufacturer.

Understanding the Role of Car Spare Parts Manufacturers

Car spare parts manufacturers are pivotal in the automotive supply chain. They not only produce essential components but also contribute significantly to vehicle safety, efficiency, and performance. Understanding their role involves looking at several key aspects:

1. Quality Assurance

One of the principal concerns for car spare parts manufacturers is ensuring that each part meets stringent quality standards. This involves rigorous testing and compliance with global regulations that govern automotive components to ensure safety and reliability.

2. Technological Innovation

As vehicles become more technologically advanced, spare parts manufacturers are compelled to adopt new technologies. Innovations in materials science, manufacturing processes, and automation have made it possible to create parts that are not only more efficient but also more sustainable. These advancements include:

- 3D Printing: Allows for rapid prototyping and the ability to create complex geometries.

- Smart Parts: Incorporating sensors and IoT technology to enhance functionality.

- Eco-Friendly Materials: Utilizing sustainable materials to reduce environmental impact.

Identifying Quality Car Spare Parts Manufacturers

When looking for reliable car spare parts manufacturers, several factors should be considered to ensure that you are making a wise choice.

1. Reputation and Reviews

Start by researching manufacturers' reputations. Customer reviews, industry feedback, and testimonials can provide insights into a manufacturer’s reliability and quality of service.

2. Certification and Compliance

Opt for manufacturers that have necessary certifications like ISO 9001, which indicates adherence to quality management standards. Compliance with local and international standards is essential for safety and performance.

3. Range of Products Offered

The best manufacturers offer a wide range of products covering various makes and models of vehicles. This diversity indicates their capability and expertise in producing different components.

4. Customer Service and Support

A manufacturer’s customer service is an important aspect. Responsive and knowledgeable support can make a significant difference when it comes to post-purchase assistance, warranties, and returns.

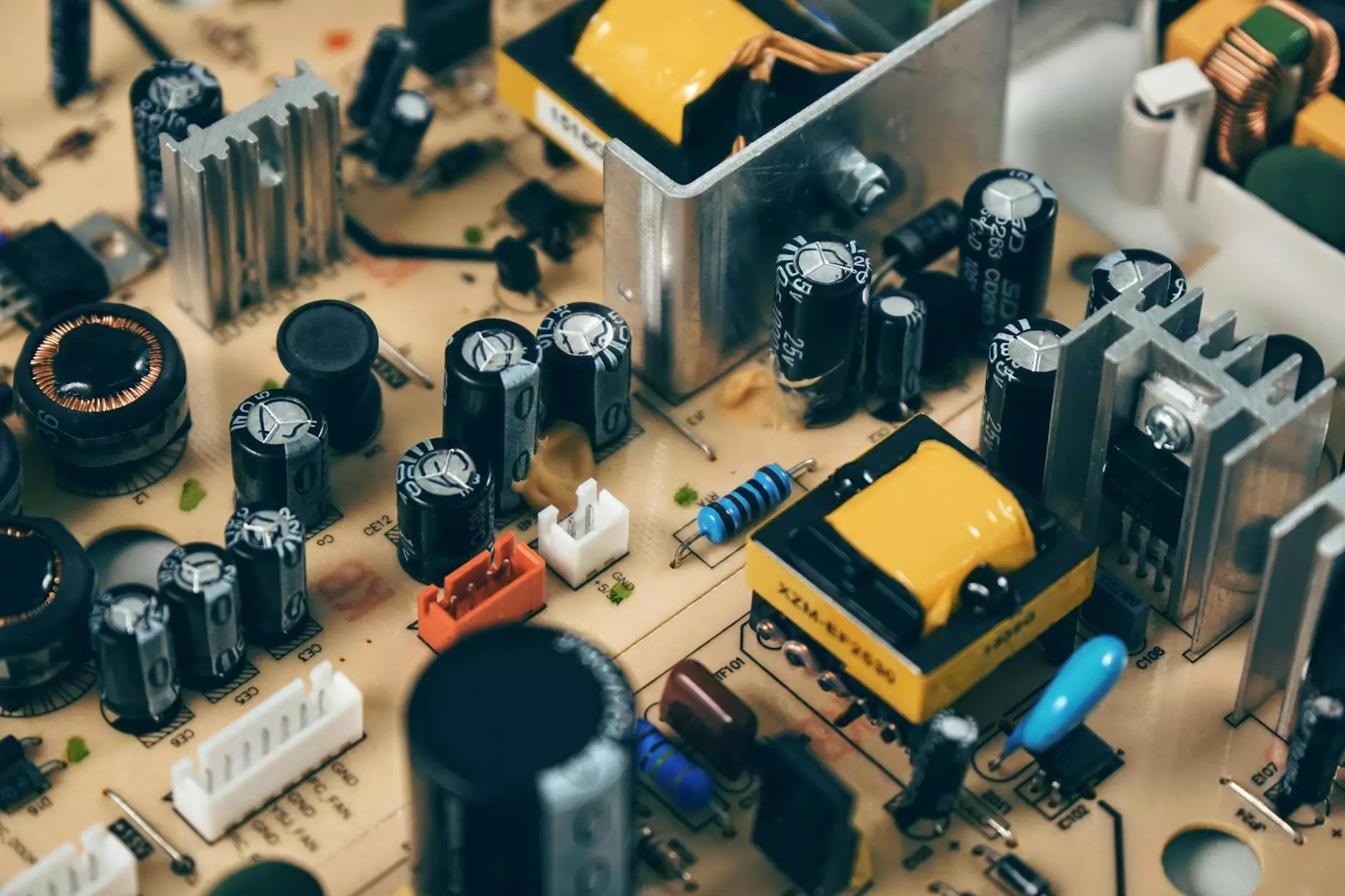

The Manufacturing Process of Car Spare Parts

The production of car spare parts involves multiple stages, each crucial for ensuring the final product's quality and reliability.

1. Design and Engineering

Every component begins with a meticulous design process. Engineers use advanced software and tools to create detailed specifications that meet the required standards for performance and safety.

2. Material Selection

The choice of materials significantly impacts the quality of spare parts. Manufacturers typically select materials based on strength, durability, and weight considerations. Common materials include:

- Aluminum: Used for lightweight components.

- Steel: Known for its strength and reliability in critical components.

- Plastic Composites: Often used in interior parts for their lightweight nature.

3. Production Techniques

The manufacturing process can involve various production techniques such as:

- CNC Machining: For precision parts.

- Stamping: For high volume metal parts.

- Injection Molding: Common for plastic parts.

4. Quality Control

After production, each batch goes through rigorous quality control checks. This may include:

- Dimensional Inspections: Ensuring each part meets defined specifications.

- Functional Testing: Verifying the performance of critical components.

- Durability Testing: Assessing how parts hold up under real-world conditions.

The Economic Impact of Car Spare Parts Manufacturing

The manufacturing of car spare parts is not just crucial for the automotive industry but also has a significant economic impact. Here are some ways it contributes:

1. Job Creation

The industry creates thousands of jobs worldwide, spanning various roles from manufacturing and engineering to sales and logistics.

2. Supporting Local Economies

Car spare parts manufacturers often source materials and services locally, further supporting local economies. This creates a network of businesses reliant on the automotive industry, enhancing economic stability.

3. Innovation and Competition

The need for high-quality parts drives innovation, leading to better and more reliable vehicle performance. Healthy competition among manufacturers fosters advancements that benefit consumers.

Conclusion: The Future of Car Spare Parts Manufacturing

As we look ahead, the future of car spare parts manufacturers seems promising. With continuing advancements in technology and an ever-growing focus on sustainability, these manufacturers are poised to keep innovating. For consumers, selecting manufacturers that prioritize quality and reliability is essential to ensure that their vehicles remain safe and efficient on the road.

If you are looking for reputable car spare parts manufacturers, consider exploring imautoparts.com. Their commitment to quality and customer satisfaction makes them a reliable choice in the auto parts and supplies market.

Further Resources

To learn more about the automotive industry and the role of spare parts manufacturers, consider exploring the following resources:

- IT Supply Chain - Insights on automotive supply chains.

- Auto Parts Warehouse - A comprehensive marketplace for auto parts.

- Automotive Parts - Industry news and updates.